Application

<Commitment to Workability and Comfort

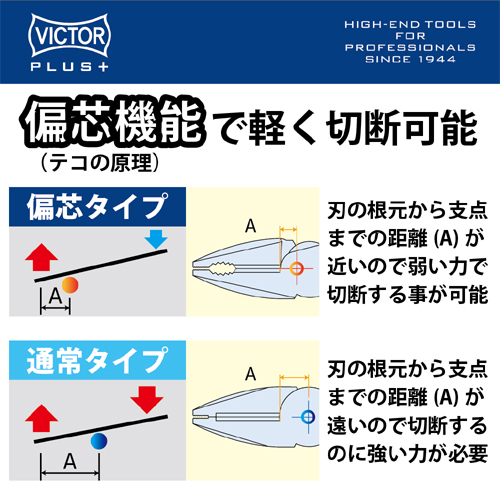

Cutting is performed many times a day. They often cut hard wire rods. The eccentric function is adopted to reduce the burden on such people.

By bringing the caulking part and the cutting part closer together, the principle of leverage is applied, enabling cutting with less force than with conventional pliers.

The grip of VICTOR PLUS is made of foam elastomer resin to soften the impact on the hand when cutting hard wire.

<Careful attention to strength and durability

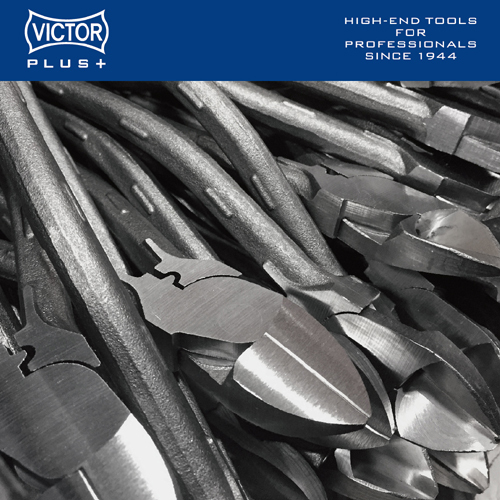

The main body of the product is made of chrome vanadium steel with high hardness and abrasion resistance. High durability is realized.

The tip of the grip has crossed-knurled grooves to ensure a firm grip.

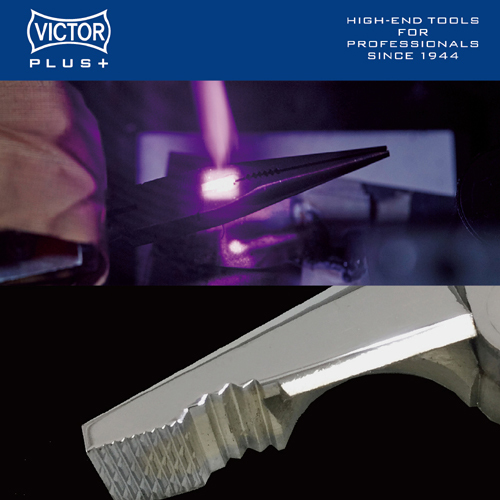

<Our commitment to durability and safety

The cutting edge is hardened by a state-of-the-art high-power laser hardening system developed by our company to minimize thermal distortion and improve the hardness of the cutting edge, resulting in excellent wear resistance.

A hole for attaching a safety rope has been made in preparation for work at high places. Since the hole is directly drilled into the steel body, there is no risk of falling.

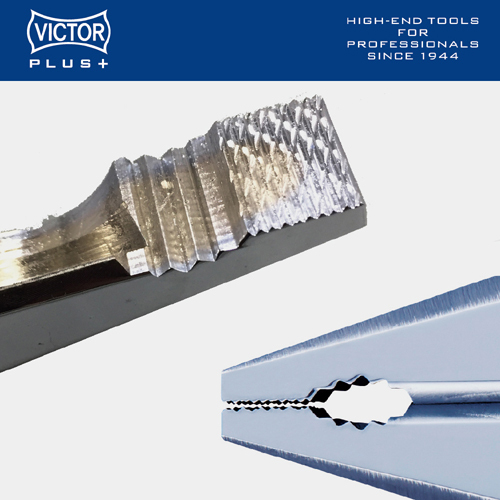

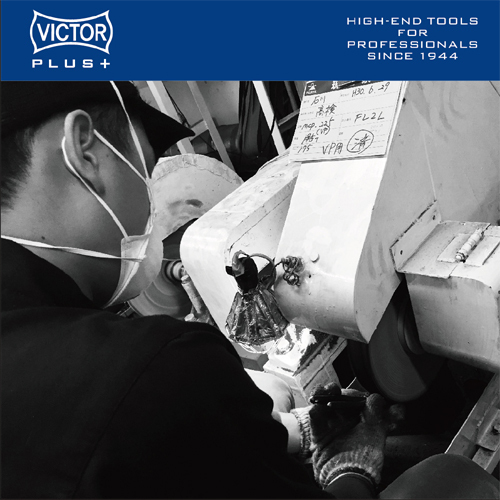

<Attention to detail in blade sharpening

Edging is the process of sharpening the blade of a product to improve its sharpness.

The slightest difference in sharpening can affect the durability and sharpness of the blade.

At VICTOR PLUS+, craftsmen with more than 15 years of experience carefully sharpen each blade to achieve the best sharpness.

<The beauty of the piece.

Each piece is polished by hand several times, until it is polished to the point that the face is visible.

The plating process is also applied to improve durability and rust resistance, as well as to create a sophisticated image.